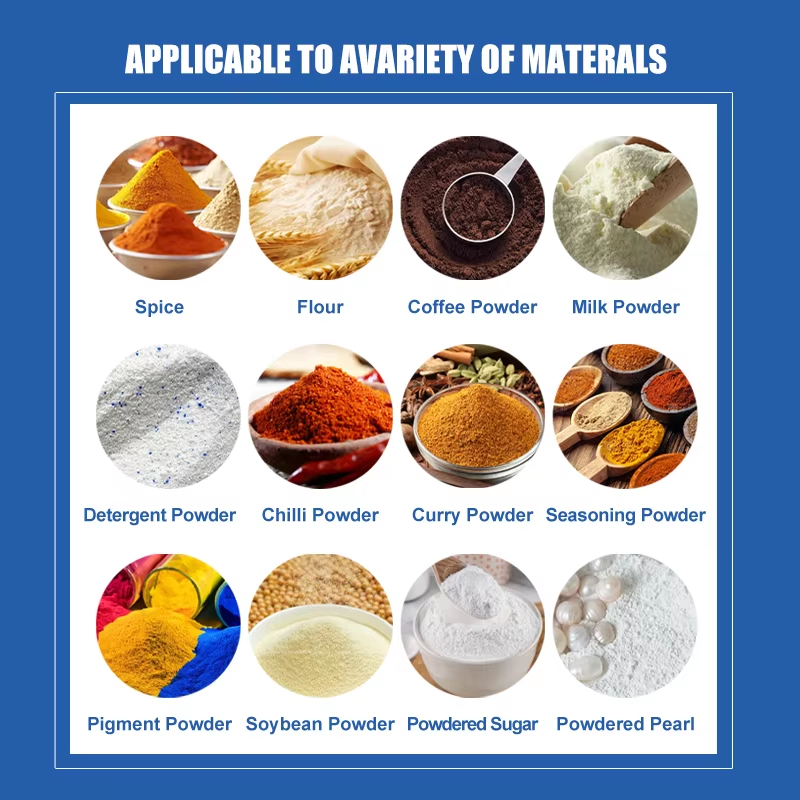

Suitable for weighing and packaging powder materials such as milk powder, coffee powder, salt, sugar, rice/wheat/corn/bean flour, detergent powder, chemical powder, medical powder, and feed additives.

| Automatic Powder Premade Pouch Doypack Filling Packing Machine | ||

| Type | YL-GD8-230/260 | |

| Bag length &width | 90-350mm(L),90-230mm(W) | 100-350mm(L),140-260mm(W) |

| Packing speed | 15-50bags/min | 15-50bags/min |

| Max weight capacity(once) | 10-2000g | 10-2000g |

| Weighing Accuracy(g) | ±0.5-1.5g | |

| Gas consumption | ≤0.8m³/min | |

| Power voltage | 380V/2500W | |

| Weight of machine | 750Kg | |

| Dimension | (L)1500mm×(W)1170mm×(H)1650mm | |

| Standard eight workstations | 1. Upper bag 2. date-printing 3.Bag opening 4. Blanking 5.Reserved 6.Reserved 7. Sealing 8. Finished product and outlet | |

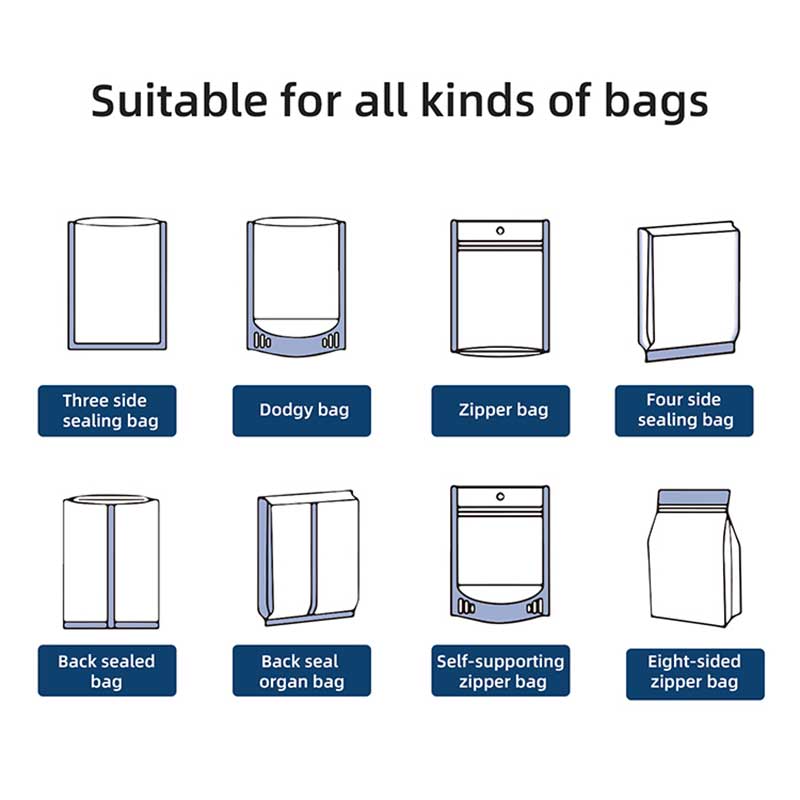

| Options | Horizontal bagging device/ zipper open/downward pouch opening device/Downward vibration/dust sweep | |