Suitable for weighing and packaging a wide range of powder materials, including milk powder, coffee powder, salt powder, sugar powder, rice/wheat/corn/bean flour, washing powder, chemical powders, medical powders, feed additive powders, and more.

| Type | YL-B320FZ |

| Max width of roll film | 300MM |

| Packing speed | 20-60bags/min |

| Packaging scope | measuring and weighing |

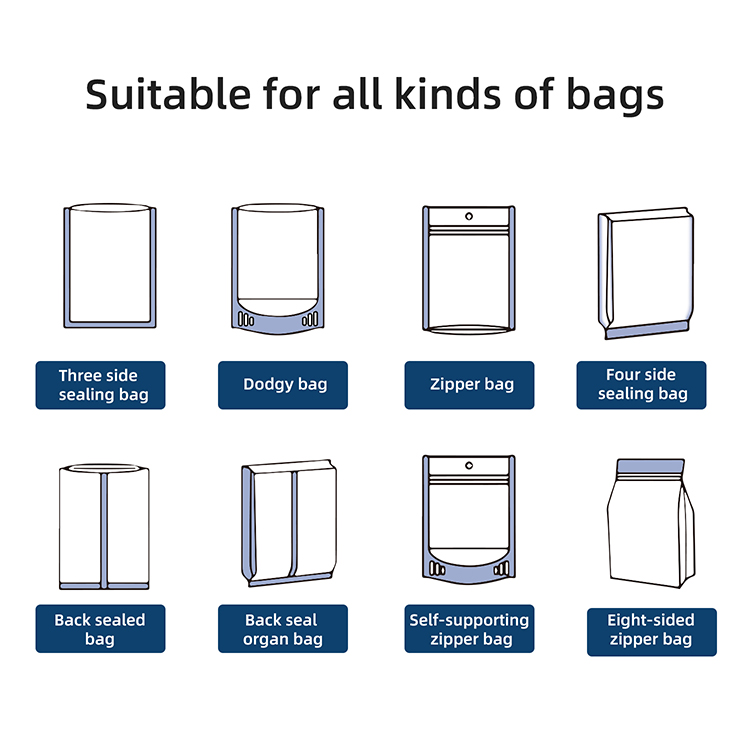

| Bag making form | Back seal/Three side seal |

| Power voltage | 220V/1.2KW |

| Package material | OPP/CPP/CE, MST/PET/PE/0.04-0.08M |

| Options | Exhaust device, Fillet cutting tools,clip-pull device/Support customization |