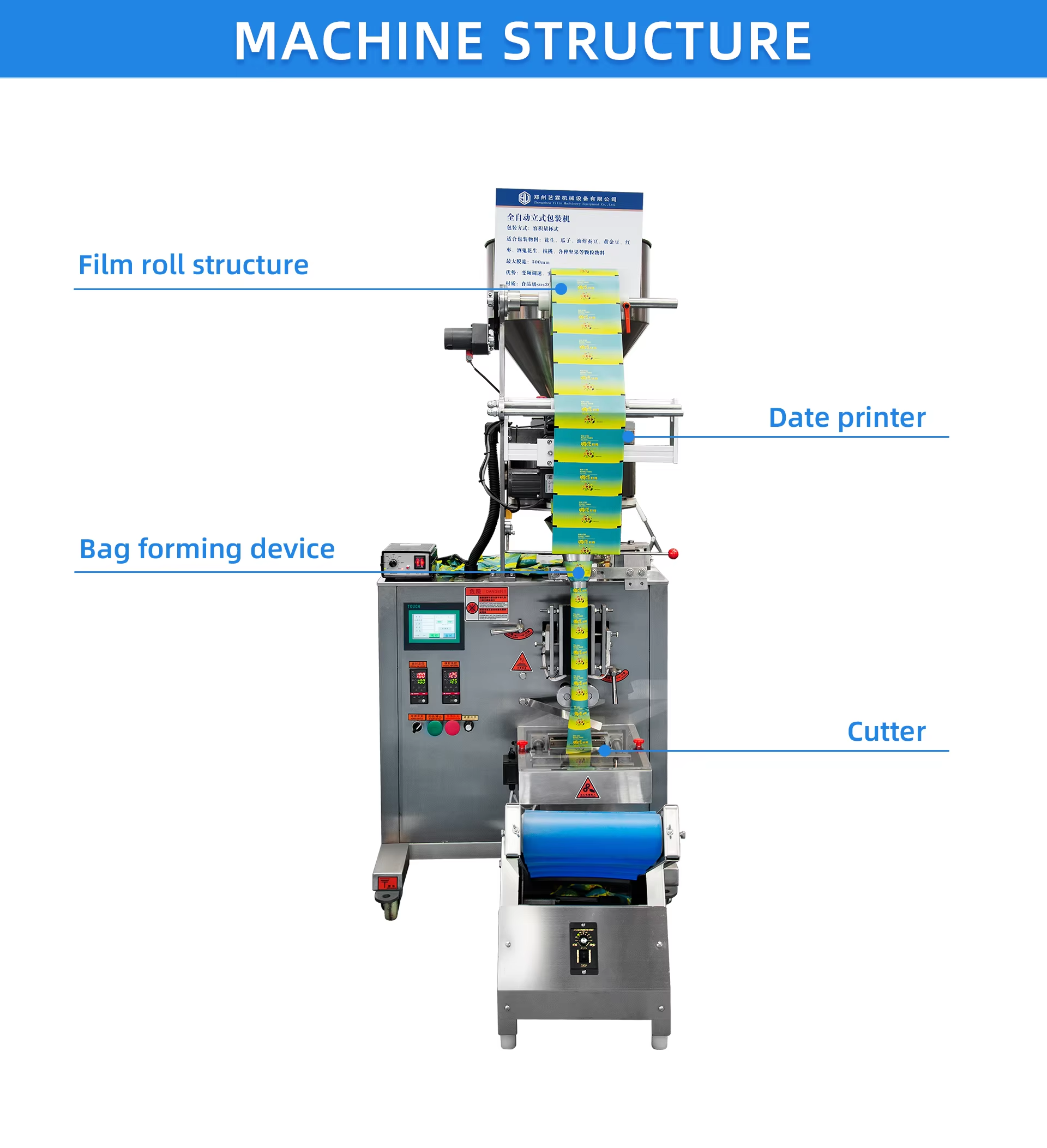

| Type | YL-S320FX |

| Max width of roll film | 300MM |

| Packing speed | 20-60bags/min |

| Packaging scope | measuring and weighing |

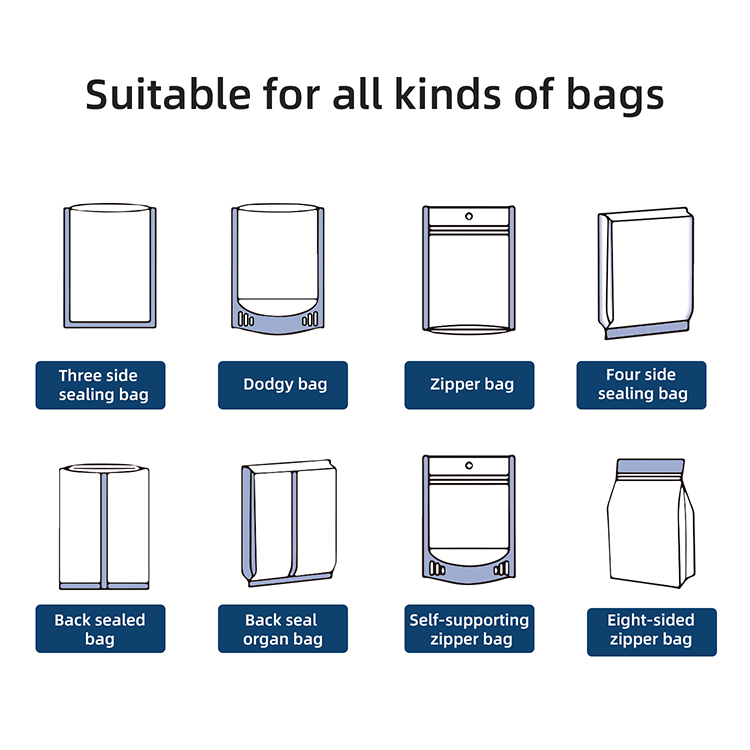

| Bag making form | Back seal/Three side seal |

| Power voltage | 220V/1.2KW |

| Package material | OPP/CPP/CE, MST/PET/PE/0.04-0.08M |

| Options | Exhaust device, Fillet cutting tools,clip-pull device/Support customization |